Glossy Finish Panels: A Comprehensive Guide

Glossy finish panels have become a popular choice in various industries, from interior design to automotive manufacturing. Their sleek, reflective surface offers a modern and sophisticated look that can elevate the aesthetic appeal of any product or space. This article delves into the world of glossy finish panels, exploring their types, applications, benefits, and maintenance. We will also discuss the technology behind their production and provide tips on how to choose the right glossy finish panel for your needs.

Table of Contents

- What Are Glossy Finish Panels?

- Types of Glossy Finish Panels

- Acrylic Glossy Panels

- Glass Glossy Panels

- Metal Glossy Panels

- Laminate Glossy Panels

- Applications of Glossy Finish Panels

- Interior Design

- Automotive Industry

- Electronics

- Furniture

- Benefits of Glossy Finish Panels

- Aesthetic Appeal

- Durability

- Easy to Clean

- Versatility

- How Glossy Finish Panels Are Made

- Manufacturing Process

- Materials Used

- Finishing Techniques

- Choosing the Right Glossy Finish Panel

- Considerations for Interior Design

- Considerations for Automotive Use

- Considerations for Electronics

- Maintenance and Care of Glossy Finish Panels

- Cleaning Tips

- Preventing Scratches and Damage

- Long-Term Care

- Future Trends in Glossy Finish Panels

- Innovations in Materials

- Sustainable Options

- Smart Glossy Panels

- Conclusion

1. What Are Glossy Finish Panels?

Glossy finish panels are flat surfaces that have been treated to achieve a high-gloss, reflective finish. This finish is typically achieved through polishing, coating, or laminating processes that enhance the natural shine of the material. The result is a smooth, mirror-like surface that can be used in a variety of applications, from home interiors to high-tech gadgets.

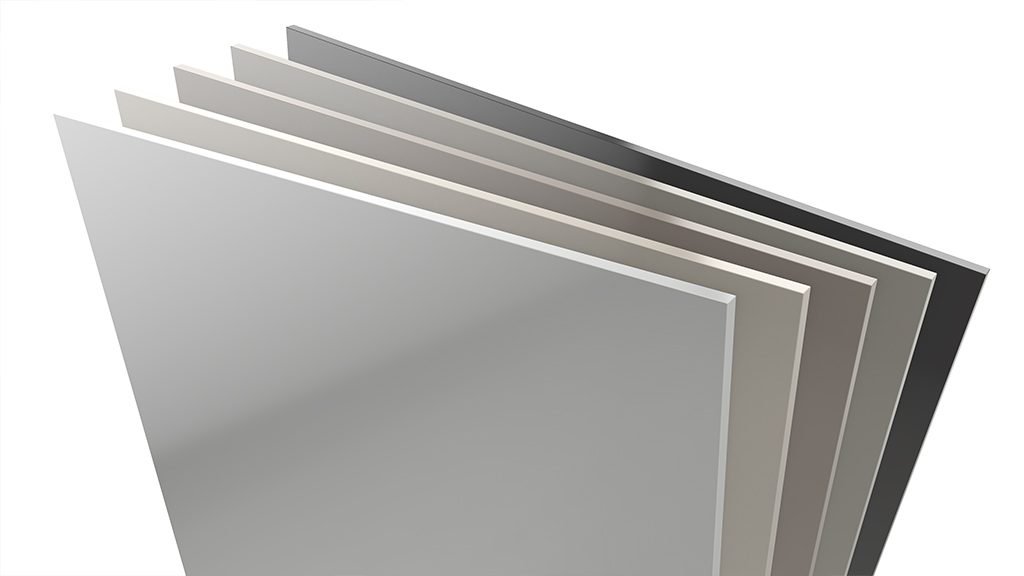

Caption: An example of a glossy finish panel used in modern interior design.

2. Types of Glossy Finish Panels

Acrylic Glossy Panels

Acrylic glossy panels are made from polymethyl methacrylate (PMMA), a transparent thermoplastic often used as a lightweight or shatter-resistant alternative to glass. Acrylic panels are known for their high clarity, UV resistance, and excellent weatherability, making them ideal for both indoor and outdoor applications.

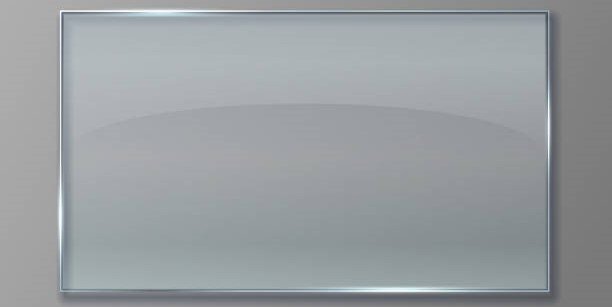

Glass Glossy Panels

Glass glossy panels are made from tempered or laminated glass that has been polished to a high shine. These panels are highly durable and resistant to scratches, making them a popular choice for high-traffic areas. Glass panels can also be treated with various coatings to enhance their reflective properties or add color.

Metal Glossy Panels

Metal glossy panels are typically made from stainless steel, aluminum, or other metals that have been polished or coated to achieve a glossy finish. These panels are known for their strength, durability, and resistance to corrosion, making them suitable for both industrial and decorative applications.

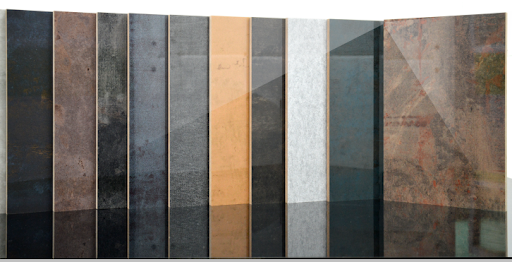

Laminate Glossy Panels

Laminate glossy panels are made by bonding a thin layer of decorative paper or fabric to a substrate, such as particleboard or MDF, and then applying a high-gloss finish. These panels are available in a wide range of colors and patterns, making them a versatile option for interior design.

3. Applications of Glossy Finish Panels

Interior Design

Glossy finish panels are widely used in interior design to create a modern, luxurious look. They can be found in kitchens, bathrooms, living rooms, and offices, where they are used for cabinetry, wall panels, countertops, and more. The reflective surface of glossy panels can help to brighten up a space by reflecting light, making rooms appear larger and more open.

Automotive Industry

In the automotive industry, glossy finish panels are used for both exterior and interior components. Exterior applications include body panels, trim, and wheels, while interior applications include dashboard panels, door inserts, and center consoles. The high-gloss finish adds a touch of elegance and sophistication to vehicles.

Electronics

Glossy finish panels are commonly used in the electronics industry for the casings of devices such as smartphones, tablets, laptops, and televisions. The sleek, reflective surface enhances the visual appeal of these devices and gives them a premium feel. Additionally, glossy panels can be engineered to be scratch-resistant and durable, making them suitable for everyday use.

Furniture

Glossy finish panels are also popular in furniture design, where they are used for tables, cabinets, shelves, and other pieces. The high-gloss finish adds a touch of modernity and sophistication to furniture, making it a popular choice for contemporary interiors.

4. Benefits of Glossy Finish Panels

Aesthetic Appeal

One of the most significant benefits of glossy finish panels is their aesthetic appeal. The high-gloss, reflective surface creates a sleek, modern look that can enhance the visual appeal of any product or space. Whether used in interior design, automotive applications, or electronics, glossy panels add a touch of elegance and sophistication.

Durability

Glossy finish panels are known for their durability. Depending on the material, they can be resistant to scratches, impacts, and corrosion, making them suitable for high-traffic areas and demanding applications. For example, tempered glass and metal glossy panels are highly durable and can withstand harsh conditions.

Easy to Clean

The smooth, non-porous surface of glossy finish panels makes them easy to clean and maintain. Unlike matte or textured surfaces, glossy panels do not trap dirt and grime, allowing for quick and easy cleaning with a soft cloth and mild detergent.

Versatility

Glossy finish panels are highly versatile and can be used in a wide range of applications. They are available in various materials, colors, and finishes, making it easy to find the perfect panel for any project. Whether you’re designing a modern kitchen, a luxury car interior, or a high-tech gadget, glossy panels offer endless possibilities.

5. How Glossy Finish Panels Are Made

Manufacturing Process

The manufacturing process for glossy finish panels varies depending on the material used. For example, acrylic panels are typically produced through a process called extrusion, where the acrylic is melted and formed into sheets. Glass panels, on the other hand, are made by heating and cooling the glass to create a tempered or laminated product. Metal panels are often polished or coated to achieve a glossy finish, while laminate panels are created by bonding a decorative layer to a substrate and applying a high-gloss coating.

Materials Used

The materials used in glossy finish panels include acrylic, glass, metal, and laminates. Each material has its own unique properties and benefits, making it suitable for different applications. For example, acrylic is lightweight and shatter-resistant, while glass is highly durable and scratch-resistant. Metal panels are strong and corrosion-resistant, and laminate panels offer a wide range of design options.

Finishing Techniques

The finishing techniques used to create glossy panels include polishing, coating, and laminating. Polishing involves smoothing the surface of the material to create a reflective finish, while coating involves applying a clear or colored layer to enhance the gloss. Laminating involves bonding a decorative layer to a substrate and applying a high-gloss finish.

6. Choosing the Right Glossy Finish Panel

Considerations for Interior Design

When choosing glossy finish panels for interior design, consider the overall style and color scheme of the space. Glossy panels can create a modern, luxurious look, but they may not be suitable for every design aesthetic. Additionally, consider the durability and maintenance requirements of the panels, especially if they will be used in high-traffic areas.

Considerations for Automotive Use

For automotive applications, consider the durability and resistance to environmental factors such as UV rays, moisture, and temperature fluctuations. Glossy panels used in car interiors should also be easy to clean and resistant to scratches and wear.

Considerations for Electronics

When selecting glossy finish panels for electronics, consider the durability, scratch resistance, and overall aesthetic appeal. The panels should be able to withstand daily use and maintain their glossy finish over time. Additionally, consider the weight and thickness of the panels, especially for portable devices.

7. Maintenance and Care of Glossy Finish Panels

Cleaning Tips

To maintain the glossy finish of your panels, clean them regularly with a soft, lint-free cloth and a mild detergent. Avoid using abrasive cleaners or scrubbers, as they can scratch the surface. For stubborn stains, use a specialized cleaner designed for the specific material of the panel.

Preventing Scratches and Damage

To prevent scratches and damage, avoid placing heavy or sharp objects on the surface of the panels. Use coasters, placemats, or protective pads to protect the surface from scratches and dents. Additionally, avoid exposing the panels to extreme temperatures or direct sunlight, as this can cause fading or warping.

Long-Term Care

For long-term care, consider applying a protective coating or sealant to the panels to enhance their durability and resistance to scratches and stains. Regularly inspect the panels for any signs of damage or wear and address any issues promptly to prevent further damage.

8. Future Trends in Glossy Finish Panels

Innovations in Materials

As technology advances, new materials and manufacturing techniques are being developed to create even more durable and versatile glossy finish panels. For example, researchers are exploring the use of nanotechnology to create self-healing coatings that can repair scratches and damage automatically.

Sustainable Options

With increasing awareness of environmental issues, there is a growing demand for sustainable glossy finish panels made from eco-friendly materials. Manufacturers are exploring the use of recycled materials, biodegradable coatings, and energy-efficient production processes to create more sustainable options.

Smart Glossy Panels

The integration of technology into glossy finish panels is another emerging trend. Smart glossy panels can be equipped with sensors, touch controls, and other features to enhance their functionality. For example, smart glass panels can switch from transparent to opaque with the touch of a button, while smart laminate panels can display digital information or images.

9. Conclusion

Glossy finish panels offer a sleek, modern, and sophisticated look that can enhance the aesthetic appeal of any product or space. With a wide range of materials, finishes, and applications, glossy panels are a versatile choice for interior design, automotive, electronics, and furniture. By understanding the different types of glossy panels, their benefits, and how to care for them, you can make an informed decision and choose the right panels for your needs. As technology continues to advance, we can expect to see even more innovative and sustainable options in the world of glossy finish panels.

This article provides a comprehensive overview of glossy finish panels, covering their types, applications, benefits, and maintenance. With the inclusion of images and detailed explanations, it serves as a valuable resource for anyone interested in incorporating glossy finish panels into their projects. Whether you’re a designer, manufacturer, or consumer, this guide will help you make informed decisions and achieve the desired aesthetic and functional results.