ISPM-15 Pallet: A Comprehensive Guide to International Standards for Wood Packaging Materials

ISPM-15 Pallet, The International Standards for Phytosanitary Measures No. 15 (ISPM-15) is a globally recognized regulation that governs the treatment of wood packaging materials (WPM) used in international trade. The standard was developed by the International Plant Protection Convention (IPPC) to prevent the spread of pests and diseases that can be transported via wood packaging materials, such as pallets, crates, and dunnage. This article provides an in-depth exploration of ISPM-15, its history, implementation, treatment methods, compliance requirements, and its impact on global trade.

Table of Contents

- Introduction

- History and Development of ISPM-15 Pallet

- Purpose and Importance of ISPM-15 Pallet

- Scope and Application of ISPM-15 Pallet

- Treatment Methods Under ISPM-15 Pallet

- Heat Treatment (HT)

- Methyl Bromide Fumigation (MB)

- Other Approved Treatment Methods

- Marking Requirements for ISPM-15 Compliance

- The IPPC Mark

- Country Code

- Producer Code

- Treatment Code

- Compliance and Certification

- National Plant Protection Organizations (NPPOs)

- Accredited Certification Bodies

- Documentation and Record-Keeping

- Challenges and Criticisms of ISPM-15 Pallet

- Implementation Challenges

- Environmental Concerns

- Economic Impact on Small Businesses

- Global Adoption and Harmonization

- Countries Implementing ISPM-15

- Regional Variations and Exemptions

- Harmonization Efforts

- Impact of ISPM-15 on Global Trade

- Reduction in Pest Spread

- Trade Facilitation

- Cost Implications for Businesses

- Future Trends and Developments

- Advances in Treatment Technologies

- Potential Revisions to ISPM-15

- Integration with Other International Standards

- Conclusion

1. History and Development of ISPM-15 Pallet

The origins of ISPM-15 can be traced back to the increasing globalization of trade in the late 20th century. As international trade expanded, so did the movement of goods across borders, often accompanied by wood packaging materials. These materials, however, became a vector for the spread of invasive pests and diseases, leading to significant ecological and economic damage in importing countries.

In response to this growing concern, the IPPC, under the auspices of the Food and Agriculture Organization (FAO) of the United Nations, developed ISPM-15. The standard was first adopted in 2002 and has since undergone several revisions to address emerging issues and incorporate new scientific findings.

The development of ISPM-15 involved extensive consultation with member countries, industry stakeholders, and scientific experts. The goal was to create a standardized approach to the treatment and marking of wood packaging materials that would be universally accepted and implemented.

2. Purpose and Importance of ISPM-15

The primary purpose of ISPM-15 is to mitigate the risk of introducing and spreading quarantine pests through wood packaging materials used in international trade. Quarantine pests are those that have the potential to cause significant harm to plants, ecosystems, and agricultural economies. By regulating the treatment and marking of WPM, ISPM-15 aims to:

- Protect Plant Health: Prevent the introduction and spread of pests that can damage crops, forests, and natural ecosystems.

- Facilitate Trade: Provide a standardized framework that allows for the smooth movement of goods across borders while minimizing the risk of pest transmission.

- Promote Environmental Sustainability: Reduce the ecological impact of invasive species that can disrupt local ecosystems and biodiversity.

The importance of ISPM-15 cannot be overstated. Invasive pests and diseases can have devastating effects on agriculture, forestry, and the environment. For example, the emerald ash borer, an invasive beetle native to Asia, has caused widespread destruction of ash trees in North America, leading to significant economic losses and ecological damage. ISPM-15 serves as a critical tool in preventing such scenarios by ensuring that wood packaging materials are free from pests before they are used in international trade.

3. Scope and Application of ISPM-15

ISPM-15 applies to all wood packaging materials used in international trade, including:

- Pallets: The most common type of WPM, used for stacking, storing, and transporting goods.

- Crates: Wooden boxes used for packaging and shipping goods.

- Dunnage: Wooden materials used to secure and stabilize cargo during transit.

- Drums: Wooden barrels used for transporting liquids and other materials.

- Skids: Wooden platforms used for moving heavy loads.

The standard applies to both coniferous and non-coniferous wood species, with some exceptions. For example, wood packaging materials made entirely from processed wood products, such as plywood, particleboard, or oriented strand board (OSB), are exempt from ISPM-15 requirements because they are considered to pose a lower risk of harboring pests.

ISPM-15 is applicable to all countries that are members of the IPPC, which includes most of the world’s trading nations. However, the implementation and enforcement of the standard may vary from country to country, depending on national regulations and the specific requirements of importing countries.

4. Treatment Methods Under ISPM-15

ISPM-15 specifies two primary treatment methods for wood packaging materials: heat treatment (HT) and methyl bromide fumigation (MB). These methods are designed to eliminate pests that may be present in the wood, ensuring that the WPM is safe for international trade.

Heat Treatment (HT)

Heat treatment involves heating the wood to a minimum core temperature of 56°C (132.8°F) for at least 30 minutes. This process effectively kills pests, including insects and larvae, by denaturing their proteins and disrupting their cellular structures. Heat treatment is considered an environmentally friendly option because it does not involve the use of chemicals.

The process typically takes place in a specialized chamber or kiln, where the wood is subjected to controlled temperatures and humidity levels. Once the treatment is complete, the wood is marked with the appropriate ISPM-15 stamp, indicating that it has been heat-treated.

Methyl Bromide Fumigation (MB)

Methyl bromide fumigation is a chemical treatment method that involves exposing the wood to methyl bromide gas in an enclosed space. The gas penetrates the wood, killing any pests present. Methyl bromide is a highly effective fumigant, but it is also a potent ozone-depleting substance, and its use is subject to strict regulations under the Montreal Protocol.

Due to environmental concerns, the use of methyl bromide for ISPM-15 compliance has been phased out in many countries, and heat treatment has become the preferred method. However, in some cases, methyl bromide fumigation may still be used, particularly for specific types of wood or in regions where heat treatment facilities are not available.

Other Approved Treatment Methods

In addition to heat treatment and methyl bromide fumigation, ISPM-15 allows for the use of other treatment methods that have been approved by the IPPC. These methods must be scientifically proven to be effective in eliminating pests and must be applied in accordance with the standard’s guidelines.

Some examples of alternative treatment methods include:

- Dielectric Heating: This method uses electromagnetic waves to generate heat within the wood, effectively killing pests.

- Microwave Treatment: Similar to dielectric heating, microwave treatment uses microwave energy to heat the wood and eliminate pests.

- Chemical Pressure Impregnation: This method involves impregnating the wood with chemicals that are toxic to pests, providing long-term protection against infestation.

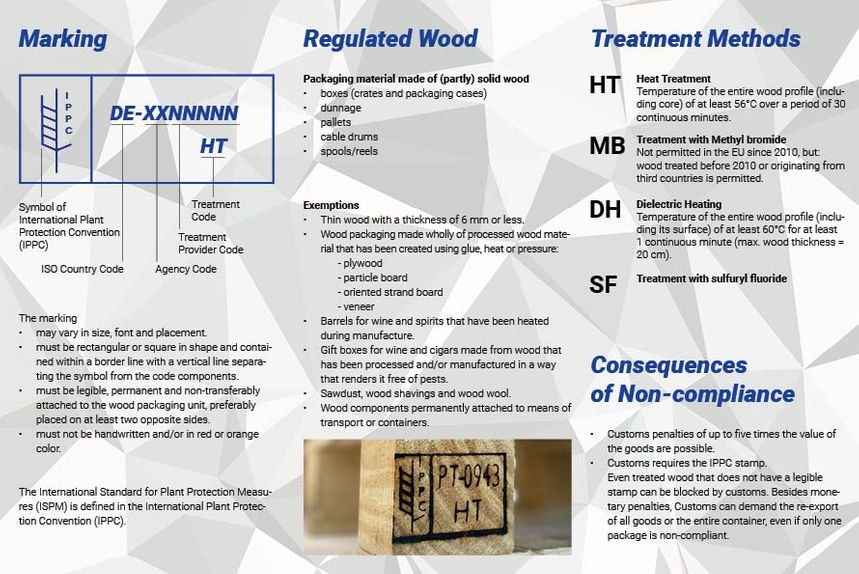

5. Marking Requirements for ISPM-15 Compliance

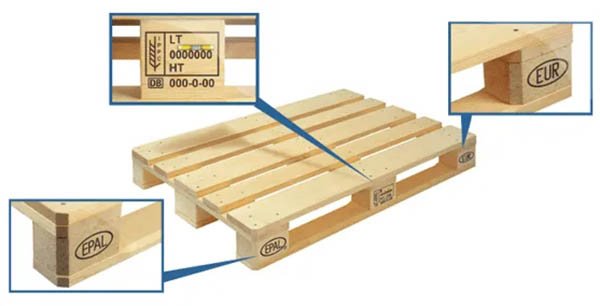

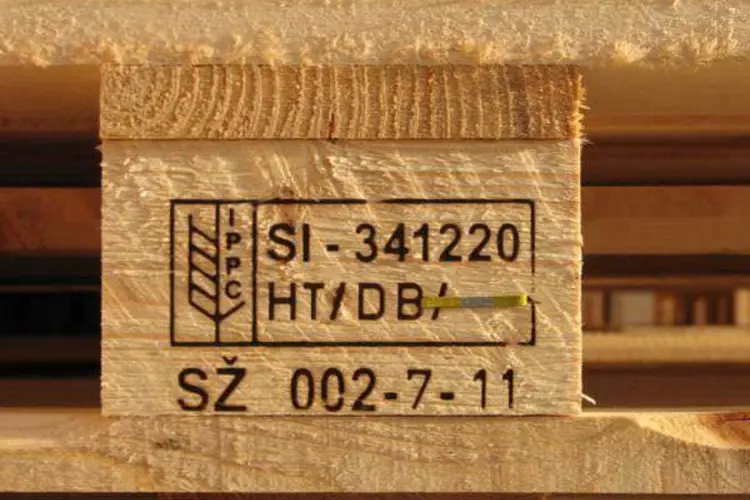

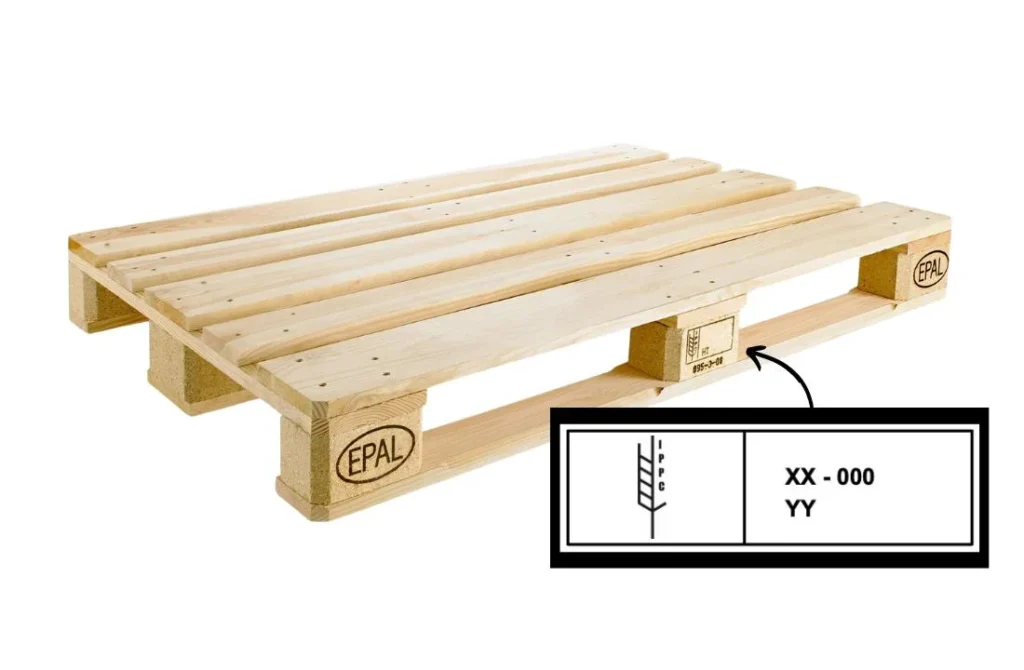

One of the key components of ISPM-15 is the requirement for treated wood packaging materials to be marked with a standardized stamp, known as the IPPC mark. This mark serves as a visual indicator that the WPM has been treated in accordance with the standard and is compliant with ISPM-15.

The IPPC Mark

The IPPC mark consists of several elements that provide information about the treatment and origin of the wood packaging material. The mark must be:

- Legible: Clearly visible and easy to read.

- Permanent: Applied in a way that ensures it will not be easily removed or altered.

- Located in a Visible Place: Placed on at least two opposite sides of the WPM, preferably near the top or bottom.

The IPPC mark includes the following components:

- IPPC Symbol: The official logo of the International Plant Protection Convention, which consists of a stylized plant with the letters “IPPC” underneath.

- Country Code: A two-letter code that identifies the country where the WPM was treated. For example, “US” for the United States, “CA” for Canada, and “CN” for China.

- Producer Code: A unique code assigned to the producer or treatment facility that performed the treatment. This code is issued by the National Plant Protection Organization (NPPO) of the country where the treatment took place.

- Treatment Code: A code that indicates the type of treatment applied to the WPM. The most common codes are “HT” for heat treatment and “MB” for methyl bromide fumigation.

Example of an IPPC Mark

An example of an IPPC mark might look like this:

IPPC

US-12345

HTIn this example:

- “IPPC” indicates that the WPM is compliant with ISPM-15.

- “US” is the country code for the United States.

- “12345” is the producer code assigned to the treatment facility.

- “HT” indicates that the WPM was heat-treated.

Additional Marking Requirements

In addition to the IPPC mark, some countries may have specific marking requirements for WPM used in international trade. For example, certain countries may require additional information, such as the date of treatment or the type of wood used. It is important for exporters to be aware of these requirements and ensure that their WPM is marked accordingly.

6. Compliance and Certification

Compliance with ISPM-15 is mandatory for all wood packaging materials used in international trade. To ensure compliance, exporters must work with certified treatment facilities and obtain the necessary documentation to prove that their WPM has been treated in accordance with the standard.

National Plant Protection Organizations (NPPOs)

Each country that is a member of the IPPC has a National Plant Protection Organization (NPPO) responsible for implementing and enforcing ISPM-15. The NPPO oversees the certification of treatment facilities, issues producer codes, and conducts inspections to ensure compliance with the standard.

Exporters must ensure that their WPM is treated by a facility that is certified by the NPPO of the country where the treatment takes place. The NPPO will issue a certificate of treatment, which serves as proof that the WPM has been treated in accordance with ISPM-15.

Accredited Certification Bodies

In addition to NPPOs, some countries may have accredited certification bodies that are authorized to certify treatment facilities and issue producer codes. These bodies work in collaboration with the NPPO to ensure that treatment facilities meet the requirements of ISPM-15.

Exporters should verify that the treatment facility they are using is certified by an accredited body and that the facility’s producer code is valid and up-to-date.

Documentation and Record-Keeping

Proper documentation is essential for demonstrating compliance with ISPM-15. Exporters must maintain records of the treatment process, including:

- Certificates of Treatment: Issued by the treatment facility, these certificates provide details of the treatment method, date of treatment, and producer code.

- Shipping Documents: Exporters should include information about the treatment of WPM in their shipping documents, such as the bill of lading or commercial invoice.

- Inspection Reports: In some cases, WPM may be subject to inspection by customs or quarantine authorities in the importing country. Exporters should retain copies of any inspection reports or certificates issued by these authorities.

Maintaining accurate and up-to-date records is crucial for ensuring smooth customs clearance and avoiding delays or penalties for non-compliance.

7. Challenges and Criticisms of ISPM-15

While ISPM-15 has been widely adopted and has contributed to the reduction of pest spread through international trade, it is not without its challenges and criticisms. Some of the key issues include:

Implementation Challenges

One of the main challenges of ISPM-15 Pallet is the variability in implementation and enforcement across different countries. While the standard provides a unified framework, the specific requirements and procedures may vary depending on the NPPO of each country. This can create confusion for exporters, particularly those who trade with multiple countries.

In some cases, countries may have additional requirements or restrictions that go beyond the scope of ISPM-15. For example, some countries may require additional treatments or inspections for certain types of wood or specific pests. Exporters must be aware of these requirements and ensure that their WPM complies with both ISPM-15 and any additional regulations.

Environmental Concerns

The use of methyl bromide fumigation as a treatment method under ISPM-15 has raised environmental concerns due to its ozone-depleting properties. While the use of methyl bromide has been phased out in many countries, it is still permitted under certain circumstances, particularly in developing countries where alternative treatment methods may not be readily available.

The environmental impact of methyl bromide has led to calls for the development and adoption of more sustainable treatment methods. Heat treatment is generally considered to be more environmentally friendly, but it requires specialized equipment and facilities, which may not be accessible to all producers.

Economic Impact on Small Businesses

Compliance with ISPM-15 Pallet can be costly, particularly for small businesses and producers in developing countries. The cost of treatment, certification, and documentation can be a significant burden, especially for businesses that rely on low-cost WPM for their exports.

In some cases, the cost of compliance may be passed on to consumers in the form of higher prices for goods. This can make it more difficult for small businesses to compete in the global market, particularly if they are exporting to countries with strict enforcement of ISPM-15.

8. Global Adoption and Harmonization of ISPM-15

Since its adoption in 2002, ISPM-15 has been implemented by over 180 countries, making it one of the most widely adopted international standards for phytosanitary measures. However, the level of adoption and enforcement varies from country to country, and there are ongoing efforts to harmonize the implementation of the standard across different regions.

Countries Implementing ISPM-15 Pallet

The majority of countries that are members of the IPPC have implemented ISPM-15, including major trading nations such as the United States, Canada, the European Union, China, and Japan. These countries have established national regulations and procedures for the treatment and marking of WPM, and they require that all imported WPM comply with ISPM-15.

In some cases, countries may have additional requirements or restrictions that go beyond the scope of ISPM-15. For example, Australia and New Zealand have particularly strict biosecurity regulations and may require additional treatments or inspections for certain types of WPM.

Regional Variations and Exemptions

While ISPM-15 provides a standardized framework, there are regional variations in how the standard is implemented. For example, the European Union has adopted ISPM-15 as part of its phytosanitary regulations, but it also has additional requirements for the treatment and marking of WPM used within the EU.

Some countries may also have exemptions or special provisions for certain types of WPM. For example, WPM made from processed wood products, such as plywood or particleboard, is generally exempt from ISPM-15 requirements because it is considered to pose a lower risk of harboring pests.

Harmonization Efforts

There are ongoing efforts to harmonize the implementation of ISPM-15 across different regions and countries. The IPPC works with member countries to promote the consistent application of the standard and to address any issues or challenges that arise.

One of the key goals of harmonization is to reduce the burden on exporters by ensuring that WPM that complies with ISPM-15 is accepted in all countries. This requires close collaboration between NPPOs, industry stakeholders, and international organizations to ensure that the standard is applied consistently and fairly.

9. Impact of ISPM-15 Pallet on Global Trade

ISPM-15 has had a significant impact on global trade, both in terms of reducing the spread of pests and facilitating the movement of goods across borders. The standard has become an integral part of international trade, and its implementation has led to several positive outcomes.

Reduction in Pest Spread

One of the most significant impacts of ISPM-15 has been the reduction in the spread of pests through international trade. By requiring that WPM be treated to eliminate pests, the standard has helped to prevent the introduction and spread of invasive species that can cause significant ecological and economic damage.

For example, the implementation of ISPM-15 has been credited with reducing the spread of the Asian longhorned beetle, an invasive pest that has caused extensive damage to hardwood trees in North America and Europe. By ensuring that WPM is treated before it is used in international trade, ISPM-15 has helped to protect forests and agricultural crops from the devastating effects of invasive pests.

Trade Facilitation

ISPM-15 has also played a key role in facilitating international trade by providing a standardized framework for the treatment and marking of WPM. The standard has helped to streamline customs procedures and reduce the risk of delays or rejections at the border due to non-compliant WPM.

By ensuring that WPM is treated and marked in accordance with ISPM-15, exporters can avoid costly delays and penalties, and they can be confident that their goods will be accepted in the importing country. This has helped to promote the smooth flow of goods across borders and has contributed to the growth of international trade.

Cost Implications for Businesses

While ISPM-15 Pallet has had many positive impacts on global trade, it has also imposed costs on businesses, particularly small and medium-sized enterprises (SMEs). The cost of treatment, certification, and documentation can be a significant burden, especially for businesses that rely on low-cost WPM for their exports.

In some cases, the cost of compliance with ISPM-15 may be passed on to consumers in the form of higher prices for goods. This can make it more difficult for small businesses to compete in the global market, particularly if they are exporting to countries with strict enforcement of ISPM-15.

However, the long-term benefits of ISPM-15, in terms of reducing the spread of pests and facilitating trade, generally outweigh the short-term costs. By investing in compliance with ISPM-15, businesses can protect themselves from the risks of pest infestations and ensure that their goods are accepted in international markets.

10. Future Trends and Developments

As global trade continues to evolve, so too will the standards and regulations that govern it. ISPM-15 is no exception, and there are several trends and developments that are likely to shape the future of the standard.

Advances in Treatment Technologies

One of the key areas of development is the advancement of treatment technologies. While heat treatment and methyl bromide fumigation are the most commonly used methods under ISPM-15, there is ongoing research into alternative treatment methods that are more sustainable and cost-effective.

For example, new technologies such as dielectric heating and microwave treatment are being explored as potential alternatives to traditional heat treatment. These methods have the potential to reduce the time and energy required for treatment, making them more accessible to small businesses and producers in developing countries.

Potential Revisions to ISPM-15Pallet

As new scientific findings